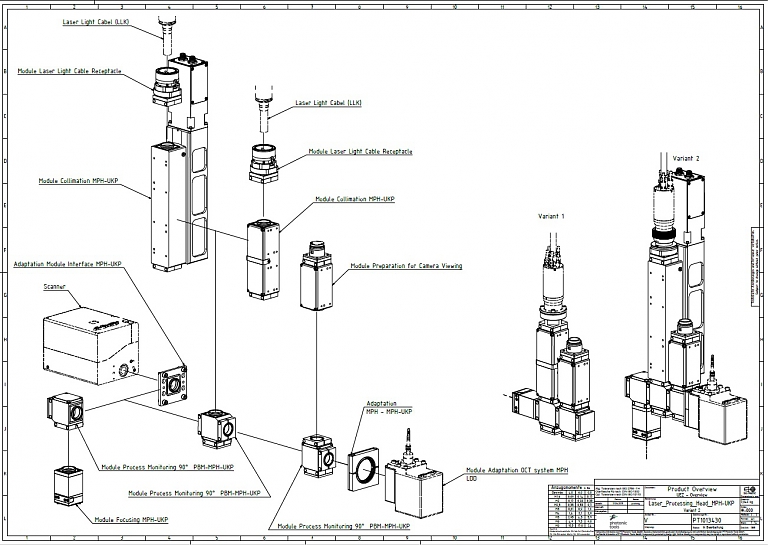

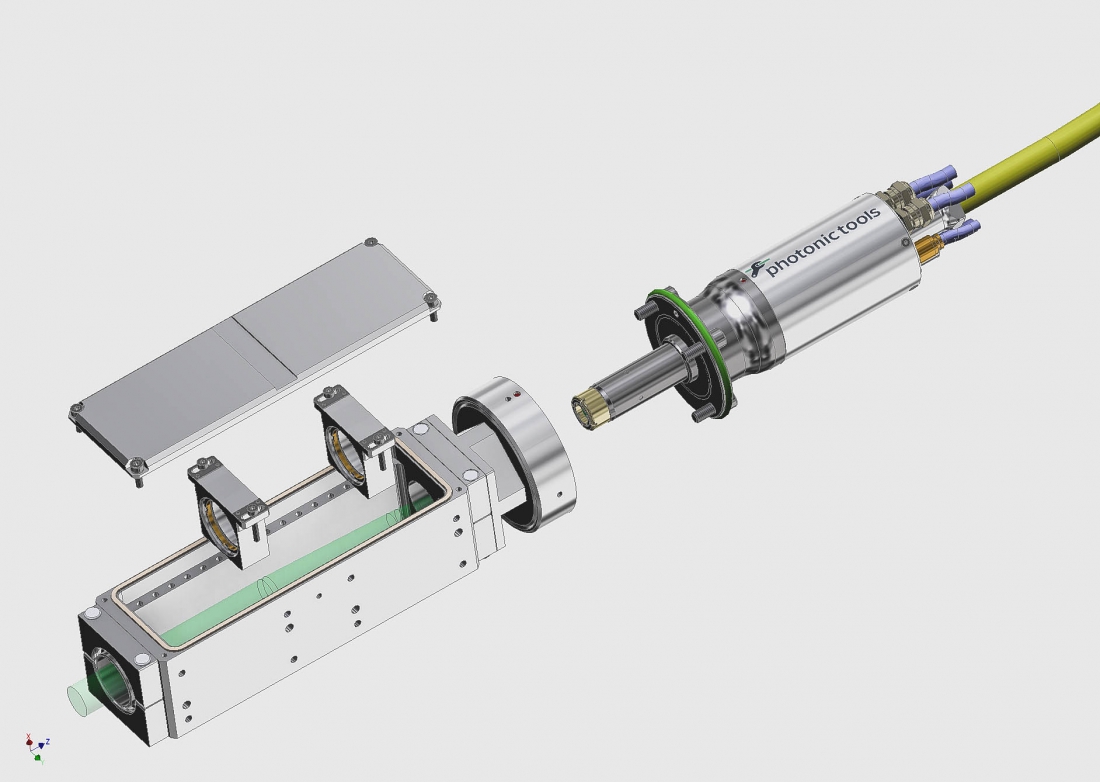

Modular laser processing head for precision applications MPH-UKP

- For fine processing applications of ultrafast, kilowatt single mode or high beam quality lasers

- Optical flexibilty for accepting the laser source and shaping the beam to the customer's individual process

- Monitoring interfaces, e.g modefield monitoring of ultrafast lasers, optical filtering for camera vison or OCT sensor adaptation

- Module interface for the cost efficient individual and reliable system integration

- Photonic Tools' unique design for simple configuration and maintenance allows a fast delivery of complex configurations and also a field service

Optical

| Overall magnification | M = Mcol x Mfoc |

| Collimation magnification Mfoc / focal length / NA (reference focal length 100 mm) | Ultrafast singlemode IR: 1,33 / 75mm / 35mrad , 1,0/100mm /35 mrad, 0,67 / 150mm /35, 0,5/ 300/35, 0,5/200/35, 0,33-0,67/150-300mm/ 35mrad, * |

| Low NA multimode IR:1,1-1,7 / 60-90mm / 120mrad, 0,6-1,1/90-170mm / 65 mrad, 0,5-0,8 / 120-205mm / 50mrad, * | |

| Low NA multimode green: 1,1-1,8 / 120-205mm / 110mrad, * | |

| Focusing magnification Mfoc/ focal length (reference focal length 100 mm) | 0,5 / 50mm, 1,0 / 100mm, 2,0 / 200mm |

| Axial focus movement range (MZ collimation) | +/- 5mm x Mfoc, depending on configuration |

| Beam parameter acceptance (half angle of laser beam exiting the fibre) |

35, 60, 125 mrad, depending on optical configuration |

| Fibre core diameter | 20 - 1500 µm |

| Wavelength | 900 - 1100 nm, 500 -550nm, * |

| Max. average laser power | 0,5 - 2 kW |

Mechanical

| Dimensions | 60 x 60 x 200 mm3, dependign on configuration |

| Weight | 2 - 6kg, depending on configuration |

| Laser light cable receptacle | LLK-B, LLK-D, PT-B, PT-D, PT-F, PT-Q, QBH |

Electrical

| Power supply | 24V / 2A |

| Communication | Canbus, TTTL, * |

Cooling

| Coolant temperature | 20 - 35°C, non condensing |

| Flow rate | 1 - 2 l/min |

Environmental

| Operating temperature | 5 - 55°C |

| Transport temperature | -25 - 70°C |

| Hunidity | <95%, non condensing |

Additional Modules

| Cover slide monitoring, camera viewing, illumination, process monitoring, laser modefield monitoring, power monitoring |

| Beam bending, scanner adaptation |

| Crossjet module, cutting nozzle module |

*others on request,

All data subject to change without prior notice